Our Sustainable Water Solutions:

For a healthier lifecycle

We have in-depth knowledge of designing and executing modern water and wastewater treatment innovations based on the newest technologies. We provide solutions for municipal and industrial sectors, small or big; we develop the best process solution for your treatment needs.

⦁ Biological Nutrient (Nitrogen & Phosphorous) Removal

In recent developments concerning global discharge requirements, one of the significant changes is the shift to nutrient removal (nitrogen and phosphorus) to prevent eutrophication. Therefore, regulations limiting the concentration of nutrients (primarily nitrogen and phosphorus) are increasingly common, particularly in watersheds that are sensitive to eutrophication.

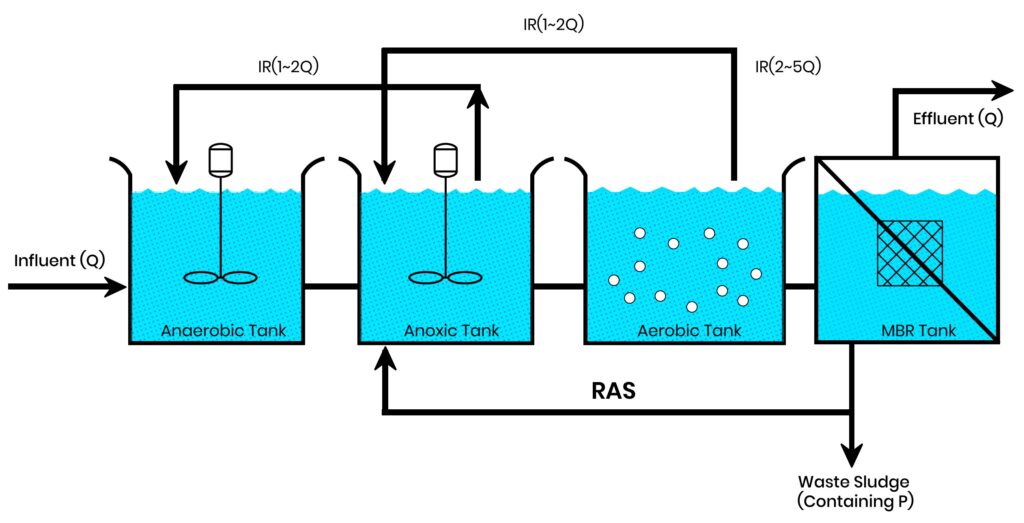

The most economical and environmentally friendly means of nutrient removal is via modifications to the conventional activated sludge process. NeerCare’s team has built projects incorporating biological nutrient removal (BNR), namely, nitrification and denitrification, and enhanced biological phosphorus removal (EBPR).

Often, the life cycle cost of a project is altered by incorporating biological nutrient removal (BNR). For example, denitrification can reduce the aeration power consumption in wastewater treatment plants and the thermal energy needed in ZLD Projects. NEERCARE’s team has the experience and expertise to comprehensively evaluate alternative process schemes to arrive at the lowest life cycle cost solution.

Biological Nitrogen and Phosphorus Removal Approaches Nitrification-Denitrification

Enhanced Biological Phosphorus Removal (EBPR)

⦁ Membrane Bioreactors

Membrane Bioreactors are an ideal choice when a compact footprint or high-quality treated water is required.

A membrane bioreactor is an activated sludge system with membranes located at the end of the activated sludge basin for liquid solids separation instead of using secondary clarifies. The key component of the integrated MBR system is the microfiltration or the ultrafiltration membrane immersed directly into the activated sludge reactor. The membranes are mounted in modules that can be lowered into the bioreactor. The advantages of the MBR system are a much smaller area requirement due to higher mixed liquor concentration of up to 12000 mg/l and the reduced space for membrane compared to clarifiers, simpler process operation with no concerns about the effect of filamentous activated sludge, and a reclaimed water quality effluent due to complete suspended solids capture across the membrane separation and lower disinfection requirement due to low turbidity.

Because of our extensive experience with membrane bioreactors (MBRs), we can design greenfield treatment systems far more compact than the conventional aeration-clarifier alternative while producing treated water suitable for reuse as cooling tower make-up water, irrigation water, and other non-potable uses. Furthermore, the treated water fulfils the silt density index (SDI) criterion for reverse osmosis input water, allowing recovered wastewater to be used in various non-potable applications (boiler feed water, clean-in-place water).

MBRs are also very effective as an upgradation technique to increase the treatment capacity of an existing biological treatment system. Maintaining a higher biomass inventory allows MBRs to more than double the capacity of an existing biological treatment system without adding new structures.

Because of our expertise with various configurations (submerged, external crossflow) and membrane materials (polymeric, ceramic), we can provide the optimal solution for the specific application.

An MBR uses only one-third of the space used in a conventional activated sludge system to treat the same volume of wastewater.

⦁ Zero Liquid Discharge

ZLD is a Complete Closed Loop for Wastewater Recycling and is ideal for recycling and reusing all wastewater. Stringent regulatory requirements and water scarcity drive the growth of zero-liquid discharge (ZLD) wastewater treatment systems.

NeerCare understands that ZLD projects are both CAPEX and OPEX intensive and that minimising reject volume reduction via membranes is essential to minimise the CAPEX and OPEX of the most expensive part of the ZLD process, i.e. the evaporator and crystalliser. Our experience designing reverse osmosis pre-treatment processes to reduce the scaling and fouling tendency of the RO feedwater permits us to upsurge RO recoveries to the feedwater’s osmotic pressure limit, thus minimising the costs linked with the evaporator and crystalliser unit processes.

Zero Liquid Discharge (ZLD): Conventional RO Vs High-Efficiency RO Conventional System

Low Life-Cycle Cost System

⦁ STPs with BIOGAS and POWER Generation through Anaerobic Digestion of Sludge

⦁ Wealth from Wastes: Energy Recovery from Wastewater

We are experts in resource recovery from wastewater, producing biogas from the anaerobic digestion of sludge. Anaerobic digestion of Sludge is an ideal process for treating high-strength sludge generated from the wastewater treatment plant and recovering energy.

NeerCare is special in implementing projects that recover resources from wastewater – energy, nutrients, and reuse quality water. For specific waste streams, this concept facilitates the wastewater generator to comply with pollution control regulations while generating revenue from the recovery and use or sale of these resources. Water conservation, net zero carbon emissions, energy neutrality, or even net energy-positive resource recovery from wastewater can help organisations meet their environmental sustainability goals. High-strength wastewater with high organic compound concentrations, such as wastewater from food and beverage manufacturing, is very well-suited to waste-to-energy projects using anaerobic digestion. Anaerobic digestion can also be used to treat high organic content solid waste, such as food waste or animal manure waste. In anaerobic digesters, organic compounds are degraded under anaerobic conditions. Under these conditions, the ecosystem of organisms in the treatment plant degrades organic matter without oxygen. A by-product of the metabolic reactions is a high-energy gas called biogas. Biogas is comprised primarily of methane and carbon dioxide and can be used to generate electricity or even further processed as Compressed Biogas (CBG), which can be used as a transportation fuel or injected into a natural gas pipeline as renewable natural gas.

Since anaerobic digestion is a net energy producer, it is more economical to treat high-strength wastewater in an anaerobic digester to reduce organic loads than using an aeration-based system where oxygen requirements (and the linked energy costs for aeration) would be high. NEERCARE team has experience building hundreds of anaerobic digester plants for various wastewater and solid waste types, focusing on wet high-rate digesters.

Urban local bodies in developing countries are less money rich. Therefore, a scientific approach is required for the biological treatment process to ensure maximum returns on investment in wastewater treatment and the increased life of a project. This is where “power-neutral” STPs pave the way forward, and time-tested cases are proving the feasibility of power-neutral STPs. Green power production from sludge biogas has numerous advantages. Firstly, it guarantees the plant is self-sustaining and benefits from earning carbon credits, a source of revenue. Secondly, the client’s operating expenditure is significantly reduced by installing biogas engines, which have an attractive payback period of four to five years. Thirdly, the digested sludge is high in organic content, and nutrients N, P and K can be sold as a natural fertiliser.

Steps occurring in Anaerobic Treatment.

⦁ Process Water Solutions: Water Recycling and Reuse

Generating reclaimed water from existing wastewater streams for reuse as process and utility water is the need of the hour. Fresh water is a limited, sometimes even rare, resource. Today the balance between water requirements and resources is a fragile one. Water resources and drinking water distribution infrastructures are constantly under new pressure from population growth, economic development, migration and urbanisation. Recycling and reuse augur well for the environment as well as for industries. The limited freshwater supply can be better prioritised by setting up reuse and recycling systems. With a focus on municipal industrial tie-ups, cash-strapped municipalities will benefit from reuse using water purchase agreements.

NeerCare’s water solutions are based on the conviction that “Water is too precious to be used just once.

We Guarantee the performance of treatment systems as our wastewater plants benefit from innovative techniques and reliable treatment processes adapted to the specific effluent.

We offer advanced tertiary treatment systems comprising Ultrafiltration, Reverse Osmosis and Nanofiltration for recycling & reuse solutions. In addition, we have expertise in providing Zero Liquid Discharge systems with Mechanical Sludge Drying and Mechanical Vapour Recompression systems for handling rejects.

NeerCare is a specialist in water treatment that develops wastewater treatment solutions adapted to local conditions, meets health standards and protects water resources and biodiversity. As well as treating water, the plants designed by NeerCare also allow wastewater reuse, where appropriate, in keeping with environmental and public health regulations.

⦁ High Recovery Reverse Osmosis: A Focus on Minimizing Rejects Volumes

Ideal for when high recovery reverse osmosis and low reject volumes are required. High Recovery Reverse Osmosis (RO) is ideal when high recovery reverse osmosis is required, but a full zero liquid discharge (ZLD) system is not desired. With high recovery, reverse osmosis typically achieves 97-98% recovery, generating low reject volumes. A High Recovery RO project differs from a ZLD project in that for a High Recovery RO project; it is not required that the reject water be further treated in an evaporator and crystalliser.

Comparison of Conventional Versus High Recovery Approaches Conventional RO

High Recovery RO (Pre-treatment to eliminate all barricades, parting osmotic pressure as the only barrier to recovery)

⦁ Desalination

The desalination Process is an approach to resolving water scarcity and is idyllic for recovering freshwater from seawater. With 97% of the Earth’s water resources being seawater, desalination can be a good solution for generating fresh water in water-scarce regions. However, generating potable water from seawater requires vigilant consideration of the pre-treatment process, as seawater’s quality and pre-treatment needs vary from place to place. NEERCARE’s access to technology partners allows us to determine the proper pre-treatment process per our client’s location.

⦁ Complex Treatment Systems

Customised Treatment Solutions are the only option for complex industrial effluents for which complex treatment schemes are required to meet objectives.

The NeerCare team understands that there is no uniform solution for different industrial effluents, particularly for complex water or wastewater treatment problems. Our technology-agnostic approach to offering process solutions to our clients enables us to customise our solutions to our customer’s specific demands. Is upfront cost, for example, more essential than life cycle cost? Are the most significant characteristics simplicity of operation and little operator attention and intervention? Is there a footprint limit at the project site, or is real estate expensive? Is there a footprint limit at the project site, or is real estate expensive? Each wastewater difficulty has multiple viable process design solutions, each with benefits and drawbacks. NEERCARE can analyse these solutions quickly and correctly and offer the best option for the consumer.

⦁ Sludge and Biosolids Treatment & Management

Describe and adopt the best treatment method for sludge reduction and recovery. By population increase and urban sprawl, water and wastewater treatment’s increasing amount of sludge is a major worry for municipal governments and operators. As a result, sludge treatment to reduce volume and convert it into recoverable goods has become required.

NeerCare helps you to define and choose the best sludge management solution for you according to the:

⦁ the origin and composition of the sludge and treatment by-products

⦁ the final destination of the sludge (recycling, recovery, disposal)

NeerCare proposes various technical solutions to recycle, destroy and recover sludge and treatment by-products:

Sludge thickening and dewatering

Sludge digestion,

Thermal, mixed, solar or mechanical drying of sludge

Sludge incineration.

⦁ Class A Sludge & Bio-crude Oil Production from Wastewater Techniques

We are in a tie-up with the innovation in resource recovery with our potential partners in producing bio-crude oil from wastewater. The intersection of wastewater treatment and energy recovery has long been a promising path for operators and utility managers. Resource recovery technology developments yield efficient methods for removing nutrients and BOD and transformative processes by which biosolids, agricultural waste, WAS, and FOG can be converted to bio-crude oil. Recent advancements at the pilot facility have demonstrated the potential to compete with thermal hydrolysis and conventional digestion technologies and yield an Energy Return on Energy invested. Developments in resource recovery technologies are leading to both efficient methods for removing nutrients and BOD and novel processes by which biosolids, agricultural waste, WAS, and FOG can be converted to bio-crude oil.

Dewatered algae are processed using a high-temperature and high-pressure process, which yields a crude bio-oil. This process is comparable to the natural process which has taken place over millions of years to convert algae, dinosaurs, and other biomass into crude oil with the pressure of sediment and rocks. Comparatively, the few minutes required for the process occur in a geologic “blink of an eye” as opposed to petroleum-based crude. The bio-oil produced can be refined to create a variety of drop-in fuels, while the biochar fraction of the processing can be used as a soil amendment. A side stream from this process is diverted for nutrient recovery or recycled into the secondary treatment process to support additional algae growth. Similarly, whole biomass could be anaerobically digested for biogas production.

⦁ Rehabilitation and Upgradation of Existing WWTPs

We are masters in providing best-fit solutions for the challenges being faced by municipalities in the rehabilitation and upgradation of existing Sewage Treatment Plants to meet the latest and stringent norms. Existing plants can be incorporated with modern technologies through innovative modifications in the process scheme, thereby increasing the capacity of the existing plant and achieving the latest stringent disposal norms, including nutrient removal.